Lets build a 3D Printer

July 19, 2013 - 7:38 pm by Joss Whittle 3D PrintingA month or so before I found out I would be starting my PhD in October I was still under the impression that I would be doing an MEng and with it another dreaded dissertation project. This time however, the project would be to do with a software engineering problem, as opposed to last years which could be either industrial, research based, or software engineering.

After much deliberation looking at the shockling short list of projects I decided that I didn’t particularly want to spend a year working on any of them. Not that they were all bad per say, just that if you’re going to spend a whole year working on a single project you best be sure you care about it.

One thing that did interest me about the projects however, a few of them involved using Arduino and embedded systems. This got me thinking, what could I do with Arduino that I could propose as my own project idea? Inspiration didn’t take long, that night I stumbled across this gem while watching random videos on Youtube.

I loved it straight off, to use Lego Technic and Mindstorm NXT to create a working CNC machine! Perhaps this would make a good masters project?

Alas the the project is very much closed source and even the designs for the machine are not available.

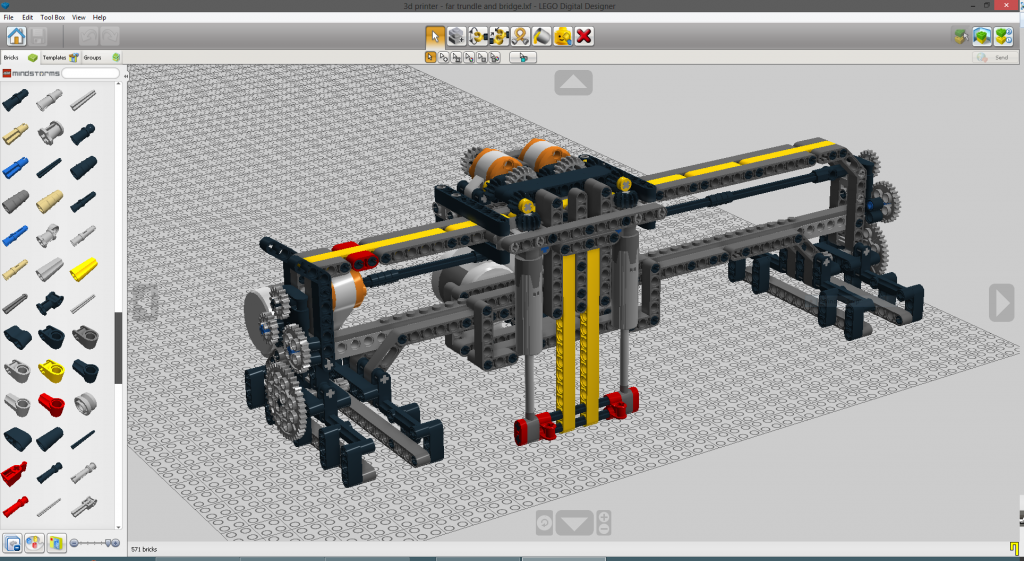

I have however, been able to reproduce the design of the machine and it’s mechanics in 3D using Lego’s 3D Autocad software, Lego Digital Designer. This was a long and painstaking process of taking screenshots of the above video and blowing them up to see the finer details (thank god for 1080p Youtube streaming) and mixing this with my methodology for how I would build this machine if I was given an unlimited set of lego. The result of my reconstruction can be seen below. While it is not a complete build (I omitted the static Y-Axis track that the carriage pictured would ride on), it is the technical majority of the machine.

I believe that this design can even be further improved upon to use less lego while allowing for a larger and more stable device to be constructed. The main limitation with increasing the track size of the device in it’s current configuration is finding a way to proportionally increase the size of the Z-Axis (vertical). Currently this axis uses two Lego Technic linear actuators to move the tool carriage up and down. However, the actuators have a fixed and limited range of climb which cannot be altered. A difference approach might be to use a threaded bar configuration to make a track which moves up and down instead with a small tensioning system to remove vibration and slack from the printing.